Pellicula composita involucri ex duabus pluribusve materiis constat, quae, post unum vel plures processus laminationis siccae, simul coniunctae, functionem quandam involucri efficiunt. Generaliter in stratum fundamentalem, stratum functionale, et stratum sigillationis caloris dividi potest. Stratum fundamentale praecipue partes aestheticas, impressionis, et impedimenti humiditatis agit, ut puta BOPP, BOPET, BOPA, etc.; stratum functionale praecipue partes impedimenti lucis, aliasque functiones agit, ut VMPET, AL, EVOH, PVDC, etc.; stratum sigillationis caloris, in contactu directo cum rebus involucris, adaptabilitatem, resistentiam penetrationi, bonam sigillationem, necnon perspicuitatem aliasque functiones agit, ut LDPE, LLDPE, MLLDPE, CPP, EVA, etc.

Usus pellicularum compositarum in variis campis adhiberi potest ad involucra industrialia, involucra quotidiana, involucra ciborum, medicinam et valetudinem, electronicam, aerospatialem, scientiam et technologiam, rem militarem, et alia. Sed sacculi compositi problema pervulgatum et difficile solvendum habent, scilicet praecipitationem pulveris albi in sacculis, quae magnum negativum impulsum in industriam involucrorum compositarum habet. Solvere hoc problema summa industriae prioritas facta est.

Solvendo Provocationem Praecipitationis Pulveris Albi in Saccis Involucrorum Cibariorum: Studium Casus in Pellicula Involucrorum Composita:

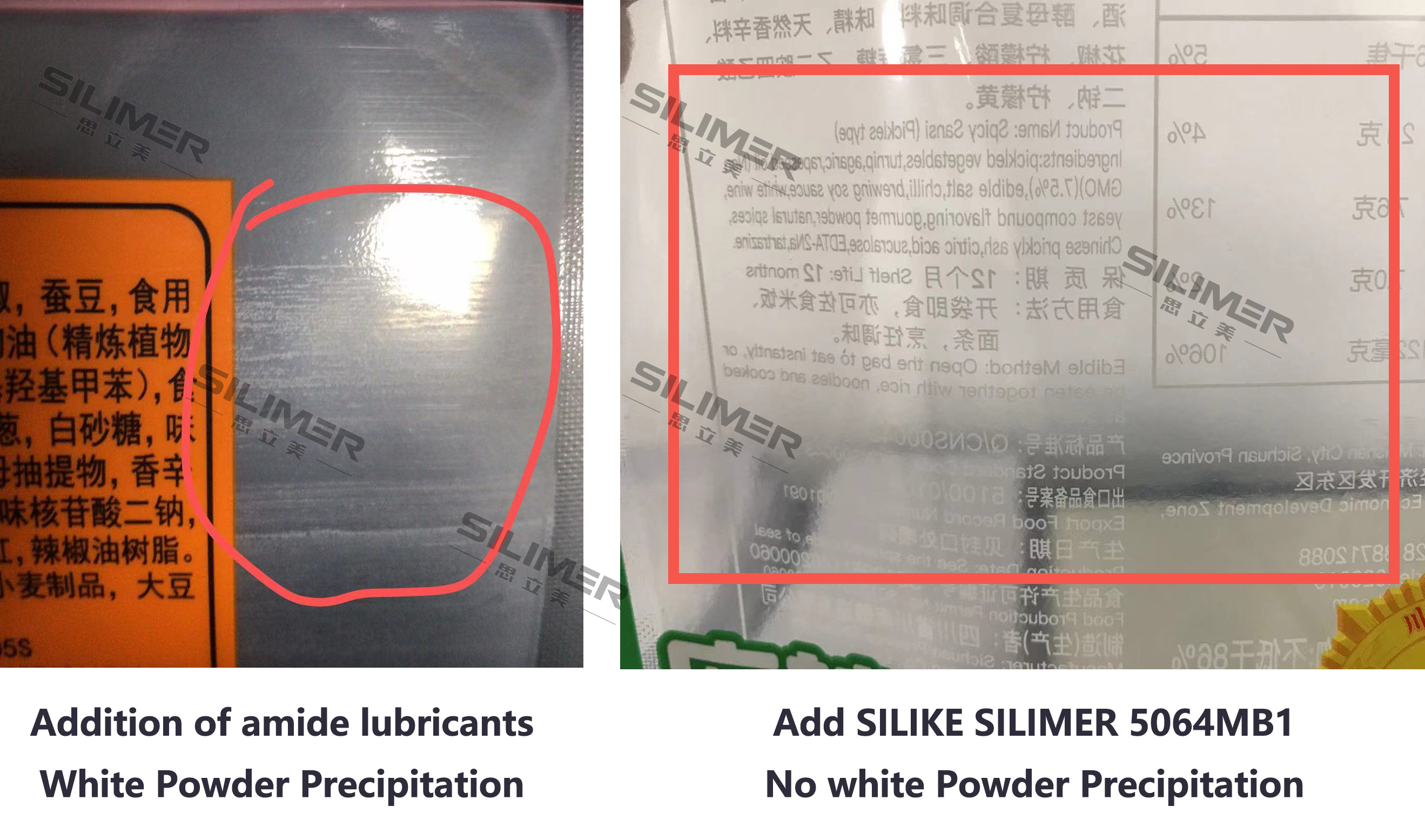

Quidam emptor, qui pelliculam compositam ad involucrum fabricat, additiva amidica, quae antea adhibita sunt, praecipitationem pulveris albi manifestam in saccis compositis effecerunt, quae et processum et qualitatem producti finalis graviter impedivit. Sed, quod magis interest, sacculi compositi ad involucrum cibarium adhibentur, quia, ob manifestam praecipitationem pulveris albi in saccis, quae cum cibo directe in contactu est, etiam salutem cibariam afficit. Itaque praecipitatio pulveris albi in saccis huic emptori valde molesta est. Sed haec causa est propter pondus moleculare parvum additivorum amidicorum et stabilitatem thermalem debilem; mutationibus temporis et temperaturae ad superficiem pelliculae migrant, ubi tandem pulverem vel substantiam ceram similem formant, quod ad manifestam praecipitationem pulveris albi in saccis compositis ducit.

Ad hanc provocationem occurrendam, SILIKE introduxitSeries SILIMER Masterbatch Super-slipSpeciatim,SILIMER 5064MB1, amixtura magistralis super-lubricabiliscum structura moleculari singulari polysiloxana copolymerizata cum gregibus organicis functionalibus activis continente, quasi res novas in pellicula composita involucrorum exstitit.

Propter parvum pondus moleculare, humilem energiam superficialem, facilem migrationem ad superficies plasticarum et partium, et moleculas cum gregibus functionalibus activis, munus ancorandi in plasticis agere potest, ad effectum consequendum.facile migrat sine praecipitatione.

Responsio deSILIMER 5064MB1positivum fuit, ab initio, adde parvam quantitatemSILIKE SILIMER 5046MB1Ad stratum obsignationis caloris, pelliculae firmitatem anti-obstructionis et levitatem insigniter augere potest, et lubricatio durante processu coefficientem frictionis dynamicam et staticam superficiei pelliculae magnopere reducere potest, superficiem pelliculae leviorem faciens, praecipitationem pulveris albi in superficie saccorum compositorum flexibilium involucrorum in involucris cibariis adhibitorum eliminans. Alia notabilis est superficies pelliculae stabilem lenemque functionem sub condicionibus altae temperaturae vel ante et post curationem habere, impressionem, obsignationem caloris, transmissionem, aut caliginem non afficiens.

SILIKE Super-slip masterbatch SILIMER 5064MB1Praecipue adhibetur in pelliculis BOPE, pelliculis CPE, applicationibus pellicularum planarum orientatarum, et aliis productis pellicularum compositarum involucrorum.

Fabricatoribus similia problemata cum pellicula composita pro saccis cibariis experientibus, SILIKE commendat ut experiantur.SILIMER 5064MB1ad experimentum exemplare.

Hoc novumSuper-lapsus MasterbatchNon solum quaestionem praecipitationis pulveris albi tractat, sed etiam efficaciam processus generalem auget, vitia et sumptus minuens.

Vetus additivum amidum labendi abice, et SILIKE contange ut explores quomodo hoc...Solutio nova "Super-slip Masterbatch"Qualitatem et salutem productorum tuorum pellicularum compositarum involucrorum augere potes!

Tempus publicationis: XIII Decembris MMXXIII