Quomodo difficultates processus materiarum funium sine halogenis et fumo parvo emittentium solvantur?

LSZH significat "low smoke zero halogens, low-smoke halogen-free" (halogenis sine fumo emissis). Hoc genus funis et filorum fumum parvum emittit et nullas halogenas toxicas calori exponit. Attamen, ut haec duo elementa clavis assequantur, in productione materiarum funium sine halogenis sine fumo emissis, halogena sine fumo emissa (LSZH) graviter onerantur, quod etiam directe ad proprietates mechanicas et processus ducit.

Difficultates in processu materiarum sine halogenis et fumo parvo emittentium:

1. Formula regularis, mixturae funium polyolefinicorum LSZH, LLDPE/EVA/ATH, alto contento repletae, usque ad 55-70% ATH/MDH continent. Cum magna copia aluminii hydroxidi, magnesii hydroxidi, aliorumque retardantium flammae ad usum systematis adsit, mobilitas systematis parva est, generatio caloris frictionalis durante processu ad augmentum temperaturae ducit, quod degradationem aluminii et magnesii hydroxidi efficit.

2. Efficacia extrusionis humilis, etiam si celeritas extrusionis augeatur, volumen fere idem manet.

3. Mala compatibilitas ignifugorum inorganicorum et impletionum cum polyolefinis, dispersio mala per processum, quae proprietates mechanicas imminuit.

4. Superficies asperitas et defectus splendoris per extrusionem propter inaequalem dispersionem retardantium flammae inorganicorum in systemate.

5.Polaritas structuralis retardantium flammarum et implentium efficit ut materia liquefacta capiti formae adhaereat, emissionem materiae e forma morans, vel moleculae parvae in formula praecipitent, accumulationem materiae in apertura formae efficientes, ita qualitatem funis afficiens.

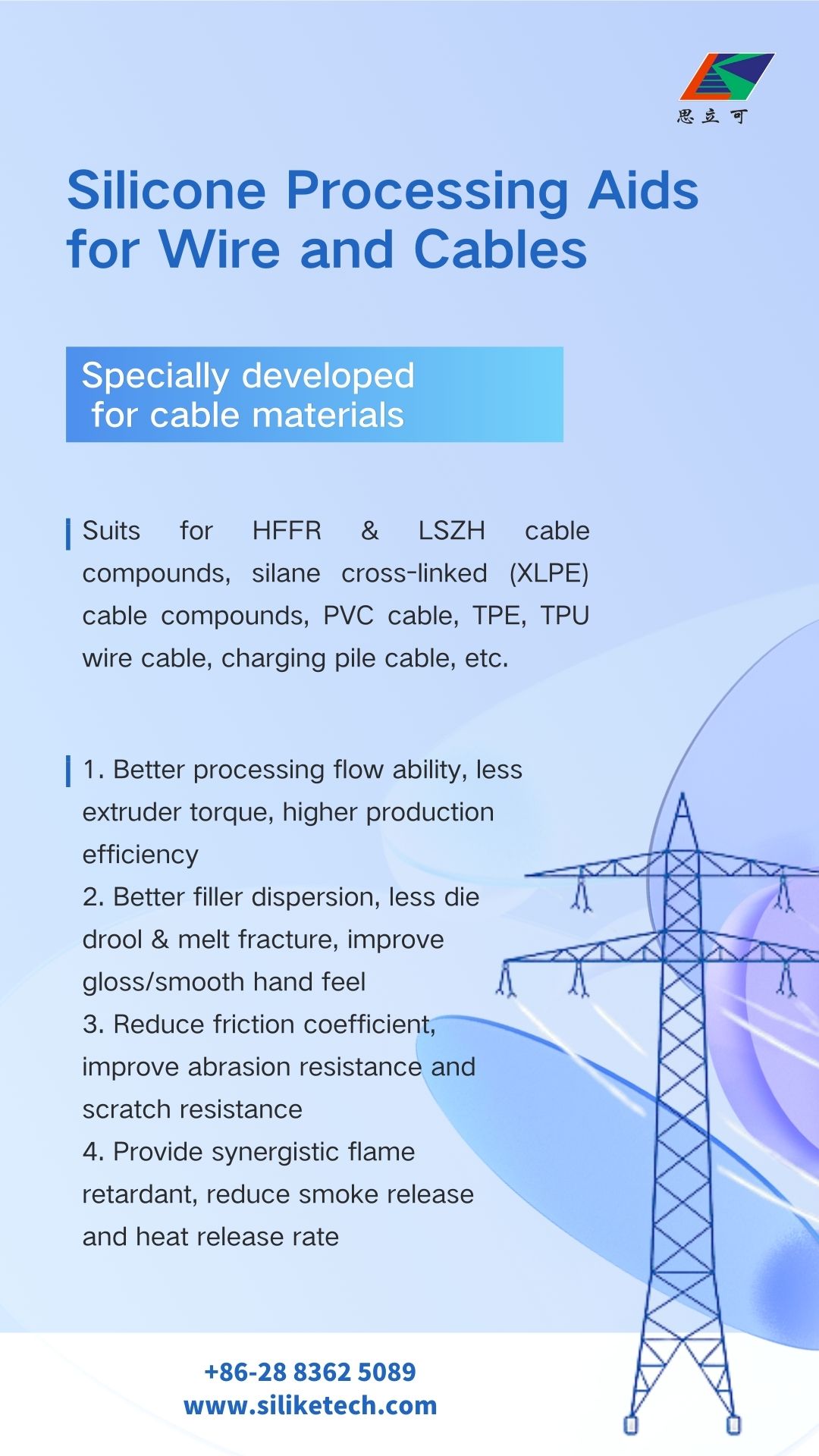

His rebus innixi, SILIKE seriem elaboravitadditivum siliconisProducta ad difficultates tractandas in processu et qualitate superficiei materiarum funium sine halogenis et fumo parvo, mixturarum filorum et funium sine halogenis et fumo parvo, vel aliorum mixturarum polyolefinicarum mineralibus valde plenarum ad usus filorum et funium specialiter designata, varietatem solutionum efficacium his provocationibus praebentes.

Exempli gratia:Magistra Siliconis (Magistra Siloxani) LYSI-401Formula granulata est, cum 50% polymeri siloxani ponderis molecularis altissimi in polyethyleno densitatis humilis (LDPE) dispersi. Late adhibetur ut additivum efficax ad processum faciendum in systematibus resinae cum PE compatibilibus, ad proprietates processus emendandas et qualitatem superficiei modificandam.

Addendo 0.5-2% deSILIKE mixtura magistralis siliconea LYSI-401Systema impletionis ignifugum valde retardans ex filis et funibus sine halogenis fumo humili vel materia funium sine halogenis fumo humili (LSZH), fabricatoribus filorum et funium permittit ut productivitatem amplificent, fluiditatem processus augeant, momentum torquens minuant, celeritatem lineae extrusionis superficialis celeriorem sine ulla migratione habeant, qualitatem superficiei fili et funis etiam meliorem reddant (coefficiens frictionis inferior, resistentia scalpturae et detritionis emendata, lapsus superficialis melior, et sensus manualis melior...) sine pretio solvendo pro additivis functionis inutilibus.

Solet, pro Ordinariomassa magistralis siliconisSiloxanum non polare est, et pleraque inter parametros solubilitatis polymerorum catenae carbonis differentiae magnae sunt; additio multitudinis ad lapsum cochlearum, lubricationem excessivam, delaminationem superficiei producti, proprietates nexus superficiei productorum in substrato inaequaliter dispersas, et cetera afficere potest.

Dum,Additiva siliconica SILIKE ponderis molecularis altissimiModificantur per greges speciales, qui eligi et aptari possunt secundum varias necessitates additivorum siliconicorum in diversis substratis. Haec series productorum munus ancorandi in substrato agere potest, ita meliorem compatibilitatem cum substrato, faciliorem dispersionem, firmiorem nexum, atque ita substrato praestantiorem functionem praebens. Cum in systematibus LZSH et HFFR adhibetur, lapsum cochlearum efficaciter vitare potest et etiam munus significans agere potest in accumulatione materiae in forma oris emendanda.

Tempus publicationis: VII Septembris, MMXXIII