Magistra mixtura nigra est pars vitalis in multis industriis, inter quas fibrae syntheticae (ut tapetes, polyester, et textilia non texta), producta pellicularum inflatarum (ut sacculi involucrorum et pelliculae fusae), producta inflata (ut vasa pharmaceutica et cosmetica), producta extrusa (inter quae laminae, tubi, et funes), et producta iniectione formata (ut partes autocineticae et apparatus electrici). Eius commoda — facilitas usus, nulla pollutio, color constans, qualitas partium plasticarum emendata, et compatibilitas cum systematibus productionis automatis — eam indispensabilem reddunt. Praeterea, magistra mixtura nigra varia additiva integrare potest, eius functionem et commoditatem augens.

Quaestiones Communes et Factores Claves de Magistris Nigris

Inter partes principales mixturae magistralis nigrae sunt niger carbonis, vector nigri carbonis, agens madefaciens nigri carbonis, dispergens nigri carbonis, et alia adiuvantia processus. Fabricatores saepe magnis difficultatibus in productione mixturae magistralis nigrae occurrunt. Quaestiones ut parva concentratio pigmenti, contaminatio per tincturam, mala dispersio nigri carbonis, et nigredo et splendor insufficientes qualitatem producti finalis afficere possunt. Haec problemata ad colorationem inconstantem, proprietates materiae imminutas, et difficultates processus ducunt.

Studium Casus: Tractatio Problematum Dispersionis in Productione Masterbatch Nigri

Nonnulli fabri mixturarum nigrarum magistralium (masterbatch) problema grave experti sunt. Formula eorum, 40% nigri carbonis continens et ceram EVA ut dispersantem utens, proprietates physicas inexpressivas per extrusionem ostendit. Nonnullae fibrae extrusae fragiles erant, aliae vero insolito tenaces, quamvis extrusore geminae cochleae uterentur et temperaturas inter 160°C et 180°C moderatas servarent. Quid problema causavit? Haec inconstantia ad problema commune in productione mixturarum nigrarum magistralium indicat: dispersionem non uniformem nigri carbonis.

Quae Est Optima Ratio Dispersionis Pigmenti Nigri Solvendae? Intellegendo Dispersionem Carbonis Nigri

Nigrum carbonis, pulvis subtilis ad pigmentandum et corroborandum adhibitus, propter aream superficialem magnam et inclinationem ad agglomerandum, dispersioni difficultatem praebet. Dispersio uniformis intra matricem polymericam assequi essentiale est ad qualitatem producti conservandam. Dispersio non uniformis ad strias, maculas, colorationem inaequalem, et discrepantias in proprietatibus physicis (ut fragilitatem vel duritiam inusitatam) ducere potest.

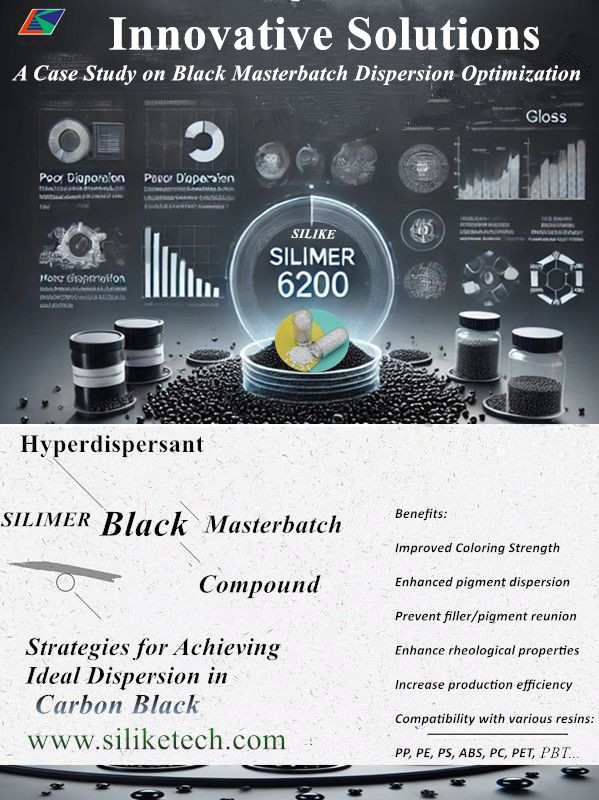

InnovativusSolutiones ad Dispersionem Uniformem in Productione Masterbatch Nigri Consequendam:Introducens Silike Silimer 6200:Hyperdispersans Probatum

Hyperdispersans SILIMER 6200Specialiter designatum est ad provocationes dispersionis pigmenti nigri et carbonis nigri tractandas, uniformitatem augendo et qualitatem generalem producti finalis amplificando.

Beneficia:

- Dispersio Pigmentorum Augmentata: Hyperdispersans SILIMER 6200dispersionem nigri carbonis emendat, colorationem constantem praebens.

- Robur Colorandi Auctum: Hyperdispersans SILIMER 6200efficaciam nigri carbonis in optatis coloribus assequendis auget.

- Praeventio Reuniones Impletionis et Pigmenti: Hyperdispersans SILIMER 6200Adiuvat ad uniformitatem conservandam, coacervationem pigmentorum prohibendo.

- Proprietates Rheologicae Meliores: Hyperdispersans SILIMER 6200Proprietates fluxus massae magistralis amplificat, processum faciliorem reddens.

- Efficacia Productionis Aucta, Sumptus Reductos: Hyperdispersans SILIMER 6200ad processum fabricationis efficaciorem confert.

Hyperdispersans SILIMER 6200Compatibilis est cum ampla varietate resinarum, inter quas PP, PE, PS, ABS, PC, PET, PBT, et plures, ita ut sit electio idealis ad latum spectrum applicationum in masterbatches et mixturis.

Don’t let dispersion issues compromise your black masterbatch product quality. Email us at amy.wang@silike.cn to learn more about how Hyperdispersans SILIKE SILIMER 6200Adiuvare te potest ut congruentes effectus consequaris et variis necessitatibus industriae tuae mixturarum magistralium et mixturarum occurras.

Tempus publicationis: XIX Novembris MMXXIV