Masterbatch NM-3C contra abrasionem solam exteriorem e gummi commoditatem et maiorem resistentiam attritionis facit.

Masterbatch NM-3C contra abrasionem solam exteriorem e gummi commoditatem et maiorem resistentiam attritionis facit.

Masterbatch anti-abrasionis NM-3C, resistentiam abrasionis solarum exteriorum augeant, colorem emendans, efficacia processus, splendor superficiei augetur, fluiditas resinae, sola exterior gummi resistentia attritionis,

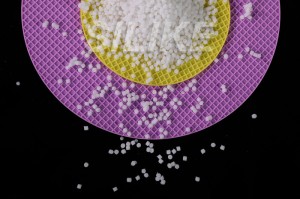

Magistra mixtura anti-abrasiva NM-3C est formula granulata cum 50% materiae activae in gummi dispersa. Praesertim elaborata est ad mixturas solarum calceorum gummi, adiuvat ad resistentiam abrasionis producti finalis emendandam et valorem abrasionis in thermoplasticis diminuendum.

Comparando cum additivis siliconicis/siloxanis minoris ponderis molecularis, ut oleo siliconico, fluidis siliconicis, vel aliis additivis abrasionis, SILIKE Anti-abrasion Masterbatch NM-3C exspectatur praebere proprietatem resistentiae abrasionis multo meliorem sine ullo effectu in duritiam et colorem.

| Gradus | NM-3C |

| Aspectus | Globulus albus |

| contentum ingredientium activorum % | 50 |

| Vector | gummi |

| Index liquefactionis (190℃, 10.00KG) g/10min | 5.10 (valor typicus) |

| Dosis % (p/p) | 0.5~5% |

(1) Resistentia abrasionis aucta cum valore abrasionis imminuto

(2) Efficientiam processus et aspectum rerum finalium confer.

(3) Oecologicus

(4) Nulla vis in duritiam et colorem

(5) Efficax ad probationes abrasionis DIN, ASTM, NBS, AKRON, SATRA, GB.

...

Applicabilis pro NR, NBR, EPDM, CR, BR, SBR, IR, HR, CSM, et cetera.

| Formula fundamentalis | NR/NBR | 40 | +NM-3C | 0 | 2% | 4% | 6% |

| Oleum machinae | 5 | Valor DIN | CLXX | 139 | 129 | 117 | |

| CB | 50 |

NM-3C cum gummi in mixtorium internum misce, dum temperatura crescit, ut aequaliter misceatur. Temperatura producta supra 100°C esse debet. NM-3C cum Si-69 adhiberi commendatur.

Cum gummi additur ad 0.2 ad 1%, melior processus et fluxus resinae exspectantur, inter quae melior impletio formae, minor torques extrusoris, lubricantia interna, liberatio formae et celerior productio; ad maiorem gradum additionis, 2~10%, meliores proprietates superficiales exspectantur, inter quas lubricitas, lapsus, minor coefficiens frictionis et maior resistentia margini/scalpturae et abrasioni.

25Kg / saccus, saccus chartaceus artificiosus

Transportandum ut chemicum non periculosum. In loco frigido et bene ventilato conservandum.

Proprietates originales integrae manent per viginti quattuor menses a die productionis, si in repositorio commendato servantur.

Chengdu Silike Technology Co., Ltd est fabricator et praebitor materiae siliconis, quae per viginti annos investigationi et evolutioni combinationis siliconis cum materiis thermoplasticis dedicata est.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnWith consumers becoming more active in their daily lives of all kinds of sports, the requirements for comfortable, and slip- and abrasion-resistant footwear has become increasingly higher. Rubber has been applied gradually in the field of sports equipment, especially in the design of sports shoes, such as running shoes, boxing shoes, and wrestling shoes, because of its favorable performance.

Additio SILIKE Anti-abrasion Masterbatch NM-3C in gummi (BR, SBR, NBR, EPDM, CR, IR, HR, CSM, NR) dum sola calceamenti fabricatur, resistentiam abrasionis solae magnopere augere et valorem detritionis minuere potest.

Examen exercitationis demonstravit calceos pressionem plantarem efficaciter minuere, dolorem localem generare posse vitari, et commoditatem augere.

Additiva siliconica gratuita et exempla Si-TPV plus quam centum gradus

Genus exempli

$0

- Quinquaginta et plus

gradus Siliconis Masterbatch

- Decem vel plures

gradus Pulveris Siliconis

- Decem vel plures

gradus Masterbatch Anti-scalpturae

- Decem vel plures

gradus Masterbatch anti-abrasionis

- Decem vel plures

gradus Si-TPV

- 8+

gradus cerae siliconicae

-

Telephonum

-

Epistula electronica

-

Whatsapp

Whatsapp

-

Summum

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

1-300x199.jpg)