Masterbatch anti-abrasionis pro sola calceamenti

Magistra mixtura anti-abrasionis pro sola calceamenti,

Masterbatch anti-abrasionis pro sola calceamenti,

Descriptio

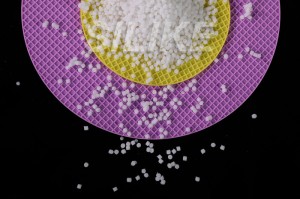

Magistra mixtura anti-abrasiva (agens anti-attritionis) NM-2T est formula granulata cum polymero siloxano UHMW 50% in resina EVA disperso. Versio emendata est prioris magistrae nostrae anti-abrasivae NM-2, cum siloxano melioris qualitatis et altiore contento siloxani. Praesertim elaborata pro systemate resinae EVA vel EVA compatibili, ad resistentiam abrasionis producti finalis emendandam et valorem abrasionis in thermoplasticis diminuendum.

Comparando cum additivis siliconicis/siloxanis minoris ponderis molecularis, ut oleo siliconico, fluidis siliconicis, vel aliis additivis abrasionis, SILIKE Anti-abrasion Masterbatch NM-2T proprietatem resistentiae abrasionis multo meliorem praebere expectatur, sine ullo effectu in duritiam et colorem.

Parametri Fundamentales

| Nomen | NM-2T |

| Aspectus | Globulus albus |

| % contenti ingredientium activorum | 50 |

| Basis resinae | Evasio |

| Dosis % | 0.5~5% |

| Applicationes | Sola EVA, PVC |

Beneficia

(1) Resistentia abrasionis aucta cum valore abrasionis imminuto

(2) Efficientiam processus et aspectum rerum finalium confer.

(3) Oecologicus

(4) Nulla vis in duritiam et colorem

(5) Efficax ad probationes abrasionis DIN, ASTM, NBS, AKRON, SATRA, GB.

Applicationes

(1) Calceamenta EVA

(2) Calceamenta PVC

(3) Composita EVA

(4) Aliae materiae plasticae cum EVA compatibiles

Quomodo uti

Masterbatch SILIKE anti-abrasionis eodem modo quo resina vecturae in qua fundatur tractari potest. In processibus classicis mixtionis liquefactae, ut extrusore cochleae singularis vel duplicis, vel iniectione formante, adhiberi potest. Mixtio physica cum granulis polymeri virginibus commendatur.

Dosis commendata

Cum additur EVA vel simili thermoplastico ad 0.2 ad 1%, melior processus et fluxus resinae exspectantur, inter quae melior impletio formae, minor torques extrusoris, lubricantia interna, liberatio formae et celerior productio; ad altiorem gradum additionis, 2~10%, meliores proprietates superficiales exspectantur, inter quas lubricitas, lapsus, minor coefficiens frictionis et maior resistentia margini/scalpturae et abrasioni.

Sarcina

25Kg / saccus, saccus chartaceus artificiosus

Repositorium

Transportandum ut chemicum non periculosum. In loco frigido et bene ventilato conservandum.

Tempus conservationis

Proprietates originales integrae manent per viginti quattuor menses a die productionis, si in repositorio commendato servantur.

Chengdu Silike Technology Co., Ltd est fabricator et praebitor materiae siliconis, quae per viginti annos investigationi et evolutioni combinationis siliconis cum materiis thermoplasticis dedicata est.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSILIKE Anti-abrasion masterbatches series is a pelletized formulation with a UHMW Siloxane polymer dispersed in SBS, EVA, Rubber, TPU, and HIPS resins, It’s particularly developed for EVA/TPR/TR/TPU/Color RUBBER/PVC shoe’s sole compounds, helps to improve the final items abrasion resistance and decrease the abrasion value in the thermoplastics. Effective for DIN, ASTM, NBS, AKRON, SATRA, and GB abrasion tests. In order to let footwear clients better understand this product’s functionality and application, we can call it silicone abrasion agent, Anti-abrasion additive, Anti-wear masterbatch, etc…

Additiva siliconica gratuita et exempla Si-TPV plus quam centum gradus

Genus exempli

$0

- Quinquaginta et plus

gradus Siliconis Masterbatch

- Decem vel plures

gradus Pulveris Siliconis

- Decem vel plures

gradus Masterbatch Anti-scalpturae

- Decem vel plures

gradus Masterbatch anti-abrasionis

- Decem vel plures

gradus Si-TPV

- 8+

gradus cerae siliconicae

-

Telephonum

-

Epistula electronica

-

Whatsapp

Whatsapp

-

Summum

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

1-300x199.jpg)